Our Story

Grizzly Iron, Inc. began as Grizzly Welding and Custom Fabrication in October of 1987. Rodger “Grizz” LaBrash started the company after he had built fencing for the home of the contractor he was working for at the time as a superintendent. Russ Horton, the contractor, bought Rodger his first welder to complete the job. He continued working for Horton Construction for some time while performing welding for side work.

In October 1987 Rodger officially started Grizzly Welding and Custom Fabrication. Grizzly performed many different small fabrication tasks from gates, fences, railings anything that involved steel and welding. Grizzly Welding worked in the

In 1996, Rodger was asked to build a driveway gate that complimented a pedestrian gate from France. This gate, which took a month to complete, had Rodger employing blacksmith techniques such as stake repoussé. This gate was what lead Rodger to move the business into forged and higher quality ironwork. Today, almost every product that leaves the shop of Grizzly Iron, Inc. has some forged ironwork even if it’s just a handle,

In 2002, Rodger lost his wife Jami to breast cancer after a

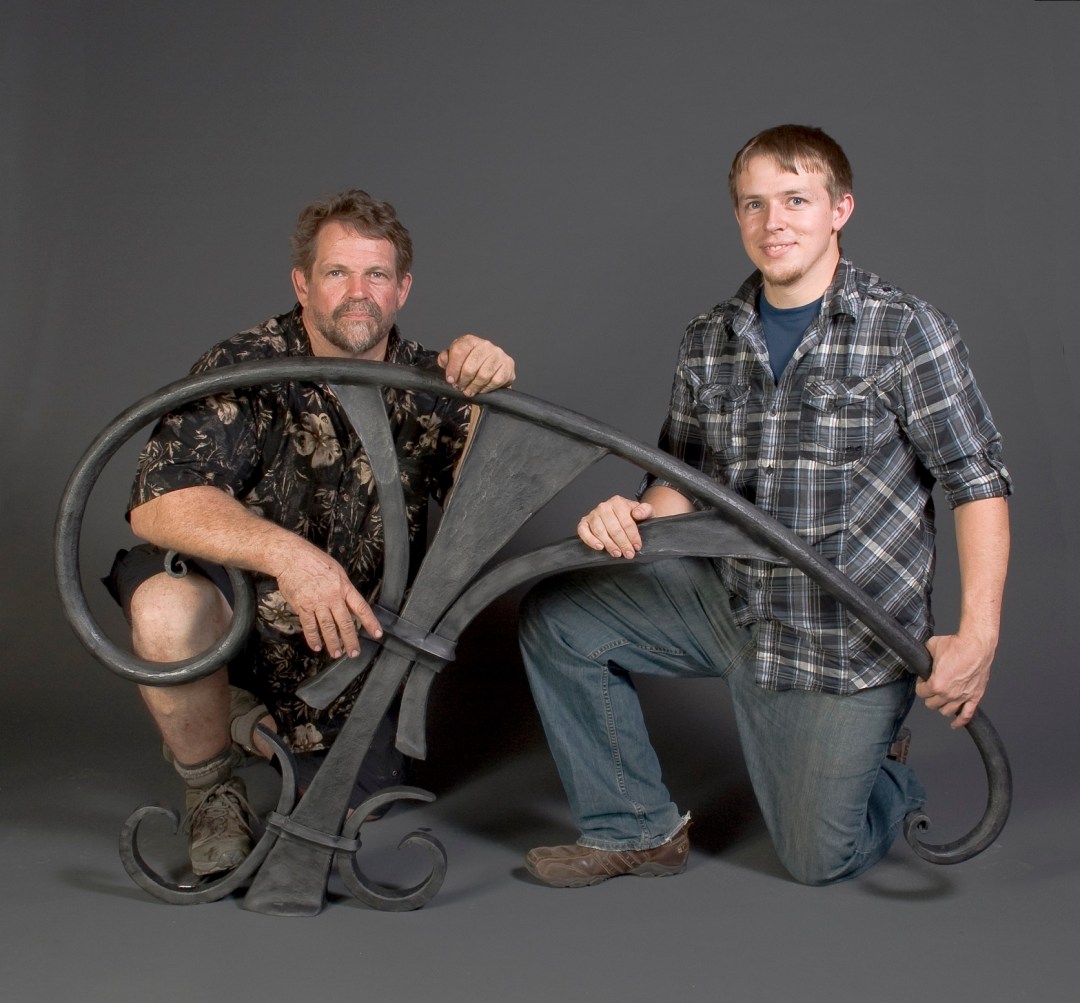

Today Grizzly Iron, Inc. is still a family run business with Rodger and son Jason working to design, fabricate, and install our client’s request for

Grizzly Iron, Inc. continues to improve and grow into one of Arizona’s largest blacksmith shops. As the clients or projects have become larger, quality has never been sacrificed.